Titanium Mesh Anodes are a reliable and economical alternative to traditional lead anodes in electrowinning operations for producing copper, nickel and cobalt metals.

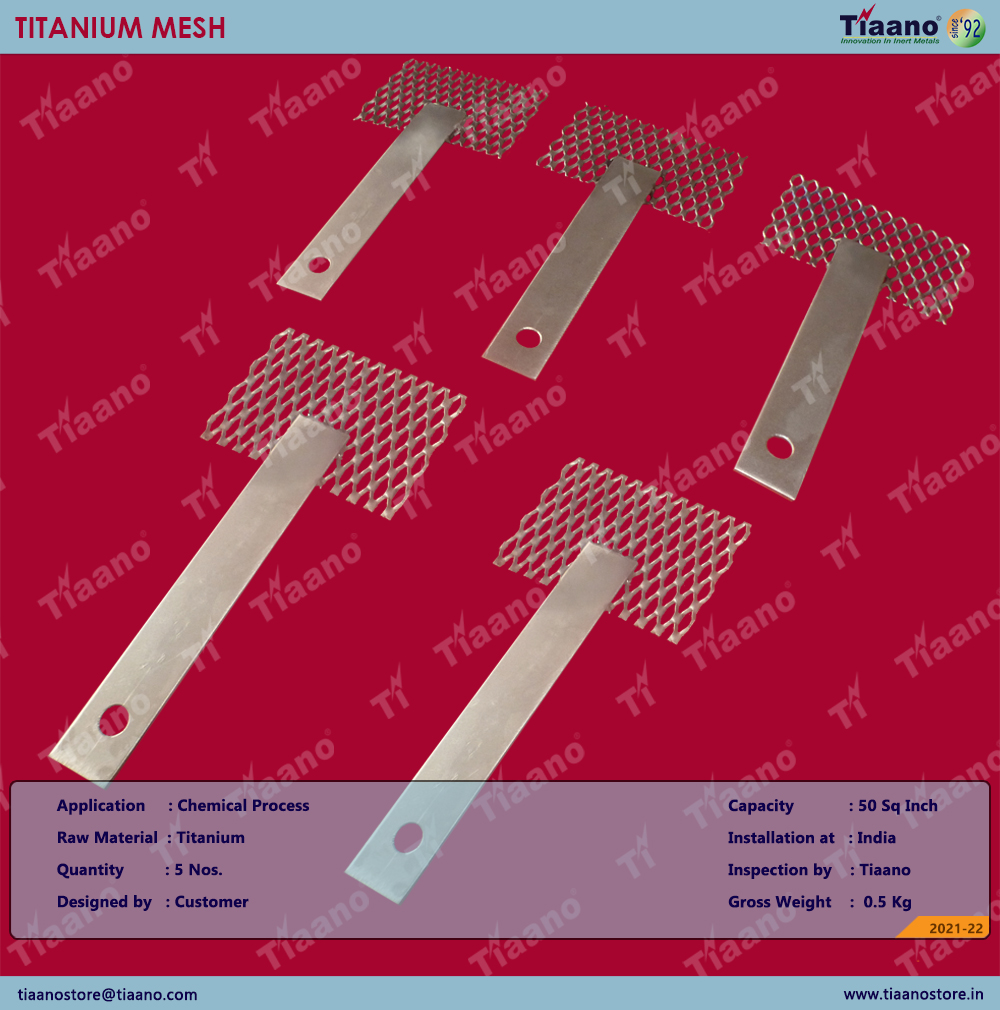

Titanium Mesh has light weight, high strength and corrosion resistance properties. These properties make it fit for use in the diverse industries. Titanium mesh can enhance the productivity process of electro plating process. Only commercially pure Titanium mesh should be utilized in anodizing applications because titanium combined with other metals causes’ contamination.

Titanium Mesh Anode Benefits:-

1. Considerable energy saving

2. Enhances sustainability

3. Decreases operational cost

4. Enhances cathode quality

Titanium Mesh Properties:-

Titanium mesh has significant durability, lightweight and corrosion resistance properties. It is used in industries such as aerospace, medical and electric industry. Generally commercially pure titanium is utilized in the anodizing applications.

Titanium mesh offers extensive resistance to salt water and is virtually immune to natural corrosion. It prevents the attack of metallic salts, chlorides, hydroxides, nitric and chromic acids and dilute alkalis. Titanium mesh can be white in colour.

Titanium Mesh Applications:-

Titanium mesh is used in many applications, such as seawater- shipbuilding, military, mechanical industry, chemical, petroleum, pharmaceutical, medicine, satellite, aerospace, environmental industry, electroplating, battery, surgery, filtration, chemical filter, mechanical filter, oil filter, electromagnetic shielding, electric, power, water desalination, heat exchanger, energy, paper industry, titanium electrode etc.

Key Features:-

1. Lightweight and excellent strength metal

2. Superior corrosion resistance than other metals

Titanium expanded metal specification range:-

Inner Opening size: Min. 1.0 mm x 2.5 mm, Max.7.0 mm x 13.0 mm

Sheet Thickness before Expanded: 0.5 mm to 2.0 mm

Expanded Thickness: 1.3 mm to 3.3 mm

Sheet size: customized sizes available