Titanium is a familiar metal. Many people know that it is used in jewelry, prosthetics, tennis rackets, goalie masks, scissors, bicycle frames, surgical tools, mobile phones and other high-performance products.

We Tiaano manufacture Titanium based products has peculiar properties. It is resistant to the passage of current into an electrolyte, but it has low resistivity when a second metal makes contact with it. If an attempt is made to use titanium as an anode in salt water, the current into the electrolyte immediately becomes apparent for an increasing anodic current is applied to it, the voltage required to force the current through the surface. Titanium is a chemical element, it can be reduced to produce a lustrous transition metal with a silver color, low density, and high strength, resistant to corrosion in sea water, aqua region, and chlorine.

Tiaano®, a well-equipped in-plant facilitated company experts in producing, chemical & Engineering Equipment’s by using inert metals of…

• Precious metal oxides ofIridium, Ruthenium, Platinum, Palladium etc.

• Exotic Metals like Titanium, Tantalum, Niobium, Zirconium, Nickel and their alloys.

• Refractory metals like Molybdenum.

• High Steel series like Duplex Steels.

One of the biggest advantages of titanium is its strength. Not only is it one of the strongest metals on the planet (rivalling even steel!), it also has the highest strength-to-density ratio of any metallic element on the periodic table. This makes it a popular option in many professions

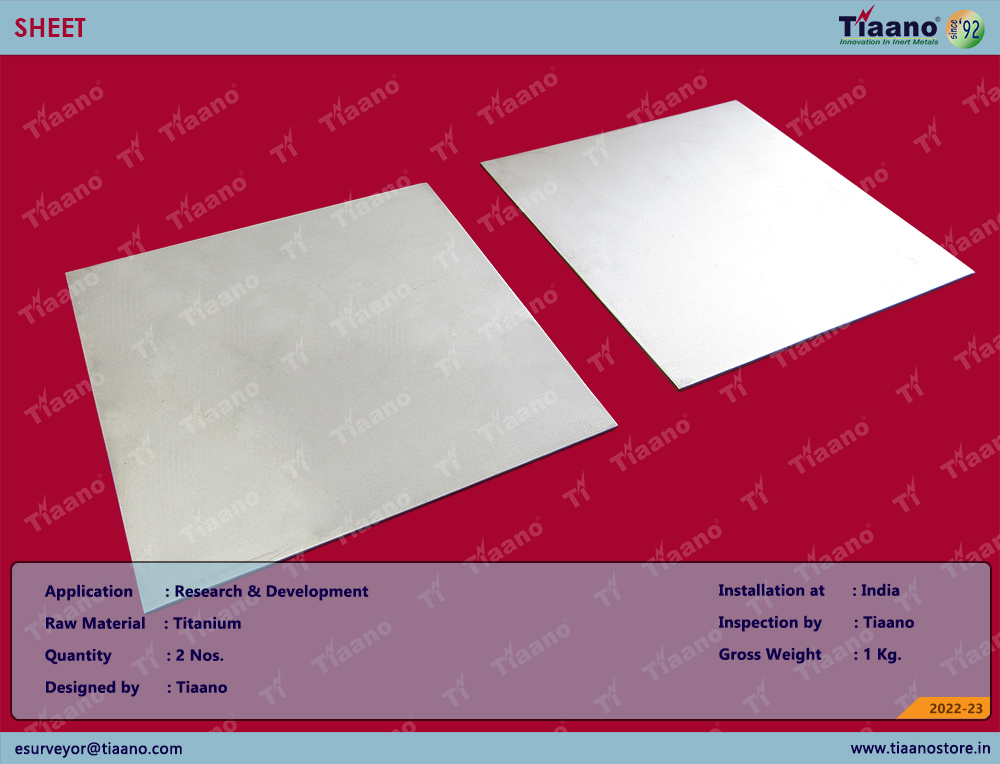

Project Details:

Designer, Manufacturer and Supplier: Ti Anode Fabricators Pvt. Ltd., Chennai

Application: Research & Development

Raw Material: Titanium

Designed by: Tiaano

Installation at: Saveetha Dental College and Hospital, Chennai